Australia is on the verge of a significant advancement in solar panel recycling, thanks to a new technology that recovers silver efficiently without damaging other components. Researchers from Macquarie University, led by Dr. Binesh Puthen Veettil and Dr. David Payne, have developed a precision extraction process that could tap into the vast amounts of silver encapsulated in the country’s discarded solar panels. As the volume of solar waste continues to increase, this innovative method promises not only environmental benefits but also substantial economic opportunities by transforming waste into valuable resources.

Macquarie University’s researchers have developed a precision silver extraction process that they say could turn the country’s growing stockpile of discarded solar panels into a major source of silver. They argue that the silver trapped inside Australia’s retired panels equals the output of the nation’s largest silver mine. With solar panel waste expected to rise sharply, this innovation could offer both an environmental and economic boost. Dr. Veettil and Dr. Payne hold a provisional patent for their method, which targets silver in panels without damaging the silicon cells, glass, or other materials, preserving them for reuse.

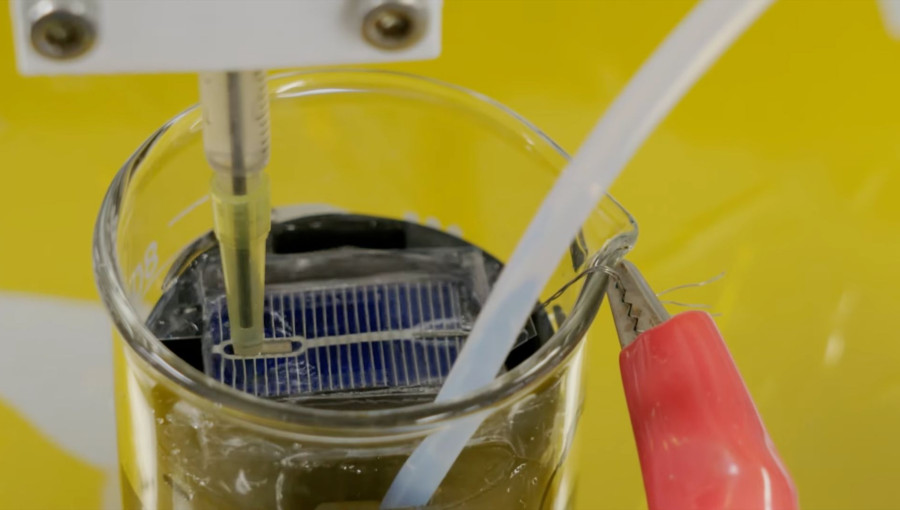

The new process works in conjunction with the team’s microwave-powered delamination technology, also licensed to Lithium Universe, and is likened to a pressure washer for removing silver. Solar panels typically last around 25 years, so many installed in the early 2000s are now nearing the end of their lifespan, creating a growing waste issue. The Australian Energy Council projects that global solar panel waste could reach between 60 and 78 million tonnes by 2050, with Australia accumulating about one million tonnes by 2035. Each panel contains approximately 20 grams of silver, which is worth roughly A$36 (US$23).

Current recycling methods often shred panels and use harsh chemicals, which damage most components, resulting in only about 15% of used solar panels in Australia being recycled. The rising demand for silver, used in electronics and renewable energy systems, further highlights the importance of recovering this metal, especially with global demand growing at about 7% annually, projected to reach 20 million kilograms by 2025. Mining doesn’t seem able to keep pace, with the market facing a shortage of 3.3 million kilograms this year and prices skyrocketing from under US$600 (A$920) per kilogram in 2018 to US$1,250 (A$1,913) today.

Through an agreement, Lithium Universe has secured the global rights to Macquarie’s technology for more than A$500,000 (US$320,000) over 20 years. The technology, known as Jet Electrochemical Silver Extraction (JESE), uses a fine stream of weak acid to dissolve silver directly from the panel surface quickly, targeting only the silver while leaving other components intact. This process ensures that the silicon wafer remains intact and uncontaminated, making it suitable for reuse in semiconductor manufacturing, which starkly contrasts with traditional recycling methods that grind panels into powder and use aggressive chemicals.

The Macquarie method preserves glass sheets and silicon wafers while effectively extracting high-purity silver. Combined with a microwave-powered delamination system, the technology can recover intact glass sheets, keep silicon wafers reusable, and extract silver with over 77% efficiency and minimal waste. Lithium Universe plans to complete its research and development and roll out commercial operations by 2032, paying annual licensing fees and a royalty on sales. The firm views this technology as essential to its vision of sustainable recycling and has established a partnership that integrates world-class research with commercial objectives, delivering a breakthrough solution for silver recovery while maintaining wafer integrity.

Veettil believes that the precision extraction process could also adapt to recover other valuable metals from solar panels, such as gallium, indium, and copper. Professor Sam Muller, Executive Dean of the Faculty of Science and Engineering, remarks on the impact that university research can have when paired with industry vision, emphasizing the innovation’s role in

https://interestingengineering.com/energy/old-solar-panels-hold-more-silver