Researchers in Germany have developed a cutting-edge fire-resistant lithium-sulfur (Li-S) solid-state battery that boasts an impressive energy density of 600 watt-hours per kilogram (Wh/kg). This innovative technology, which aims to revolutionize storage systems for electric vehicles, drones, and portable devices, is being advanced by scientists at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden. The initiative is funded through two projects: AnSiLiS, supported by the German Federal Ministry of Research, Technology and Space, and TALISSMAN, backed by the European Union’s Horizon Europe program.

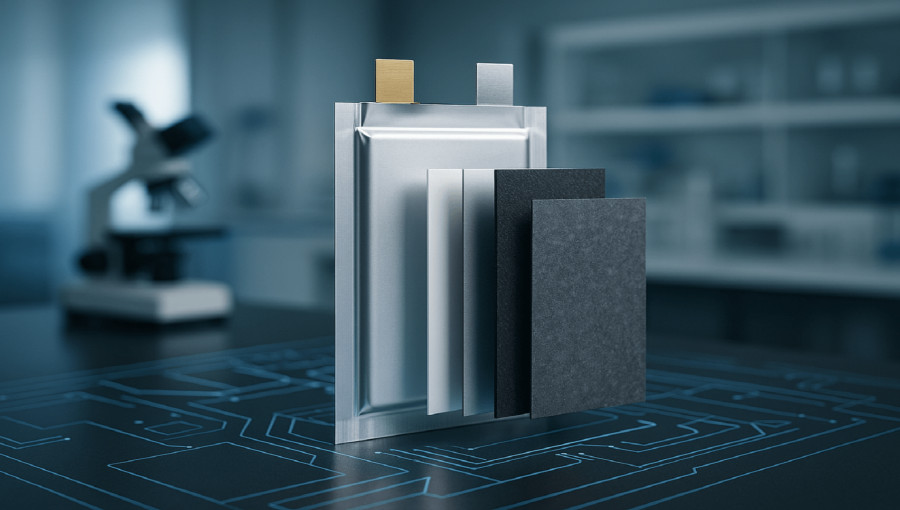

Lithium-sulfur batteries are regarded as a promising alternative to traditional lithium-ion batteries, with the potential for energy densities that can be twice as high. The new solid-state design addresses challenges that have hindered the commercial use of Li-S batteries, such as the detrimental byproducts formed from conventional liquid electrolytes. By primarily utilizing solid materials instead of liquid ones, the new battery enhances safety, stability, and energy efficiency while maintaining a light weight, crucial for applications in aviation and other mobile technologies.

The projects combine fundamental chemistry research with industrial testing. In the AnSiLiS project, a sulfur-carbon composite cathode is developed alongside a thin lithium-metal anode. Meanwhile, TALISSMAN focuses on scaling production to make commercial viability achievable, targeting an energy density of 550 Wh/kg at production costs below €75 (USD 86) per kilowatt-hour.

The production process incorporates Fraunhofer’s DRYtraec technology, which employs a solvent-free coating technique that reduces energy output by as much as 30% and reduces carbon dioxide emissions. This method is suitable for large-scale industrial production and can easily integrate with existing lithium-ion battery manufacturing processes, facilitating a quicker market entry.

All prototype testing and development efforts are centralized at the Advanced Battery Technology Center in Dresden, where the facility supports comprehensive material design and testing procedures. The research team anticipates that their new battery technology could be a game-changer for various sectors, including aviation and portable energy systems, where a high energy-to-weight ratio is vitally important. The first operational prototypes are projected to be available in the near future.