The PEARL project has made significant strides in developing flexible perovskite solar cells, achieving over 21% efficiency amidst its three-year timeline. Recent results indicate remarkable power conversion efficiencies, with different research institutions contributing innovative methods, and significant advancements in scalability and stability. The project emphasizes sustainability through the use of recycled materials and aims to reduce its carbon footprint while furthering the viability of perovskite cells for practical applications. Future efforts will focus on enhancing production techniques and field testing.

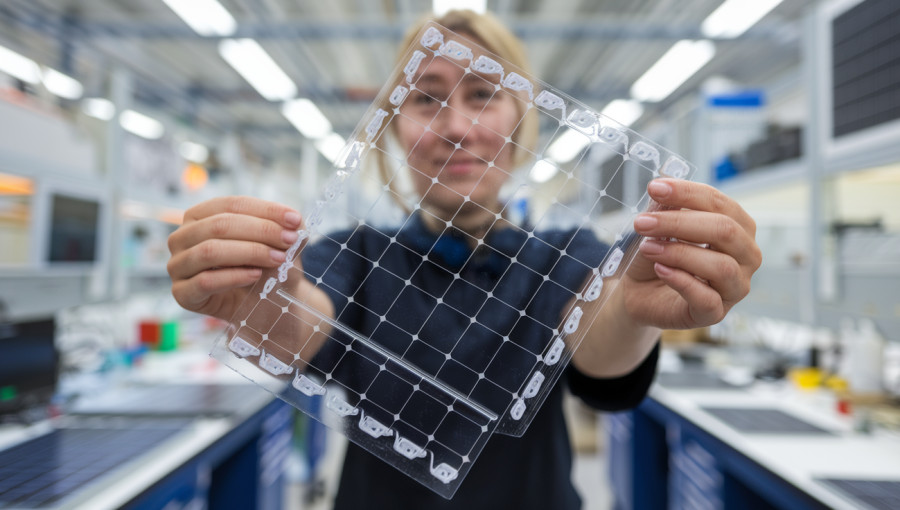

Building on earlier coverage of the EU’s PEARL project, new results at month 18 of its three-year run reveal progress towards the consortium’s ambitious goals for flexible perovskite solar cells with carbon electrodes. By leveraging advanced materials research and pilot-scale roll-to-roll manufacturing, PEARL has delivered key technical achievements with direct impact on scalability, efficiency, and sustainability. The researchers have now fabricated solar cells on flexible PET substrates that surpass 21% efficiency. Notable advances include a record 21.6% power conversion efficiency by Spain’s ICIQ using molecular surface passivation, 17.03% by Rome Tor Vergata with green perovskite solvents, and 14.8% by VTT through a gravure-printed process. The Dutch TNO group achieved 9.1% efficiency using fully roll-to-roll coating, while minimodules of 36 cm² have displayed 4.5% efficiency.

Stability has also improved, with protective encapsulation keeping devices operational for over 2,000 hours under harsh damp-heat conditions. These milestones bring PEARL’s flexible perovskite modules well within reach of the 25% efficiency target and demonstrate their viability for real-world applications such as building-integrated photovoltaics and IoT. The project’s sustainability focus is highlighted: preliminary life cycle analyses show that the use of recycled PET, carbon electrodes, and green energy can halve the carbon footprint. Protocols for recovering lead and cesium from production waste further advance PEARL towards a circular manufacturing model. Looking ahead, the consortium will ramp up roll-to-roll pilot manufacturing, test larger modules outdoors, and present results at a European conference.